We are able to produce tools up to 100 tons.

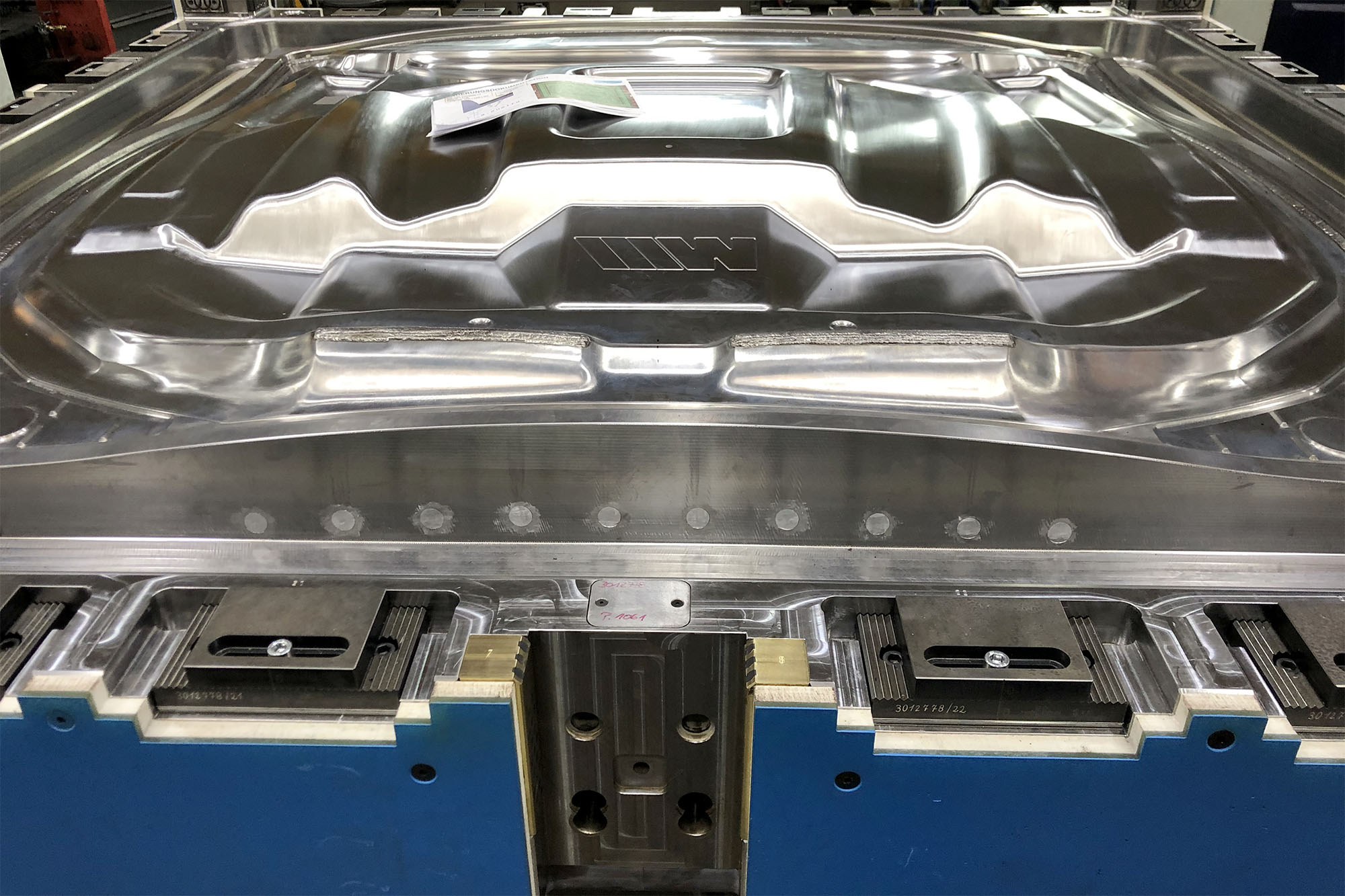

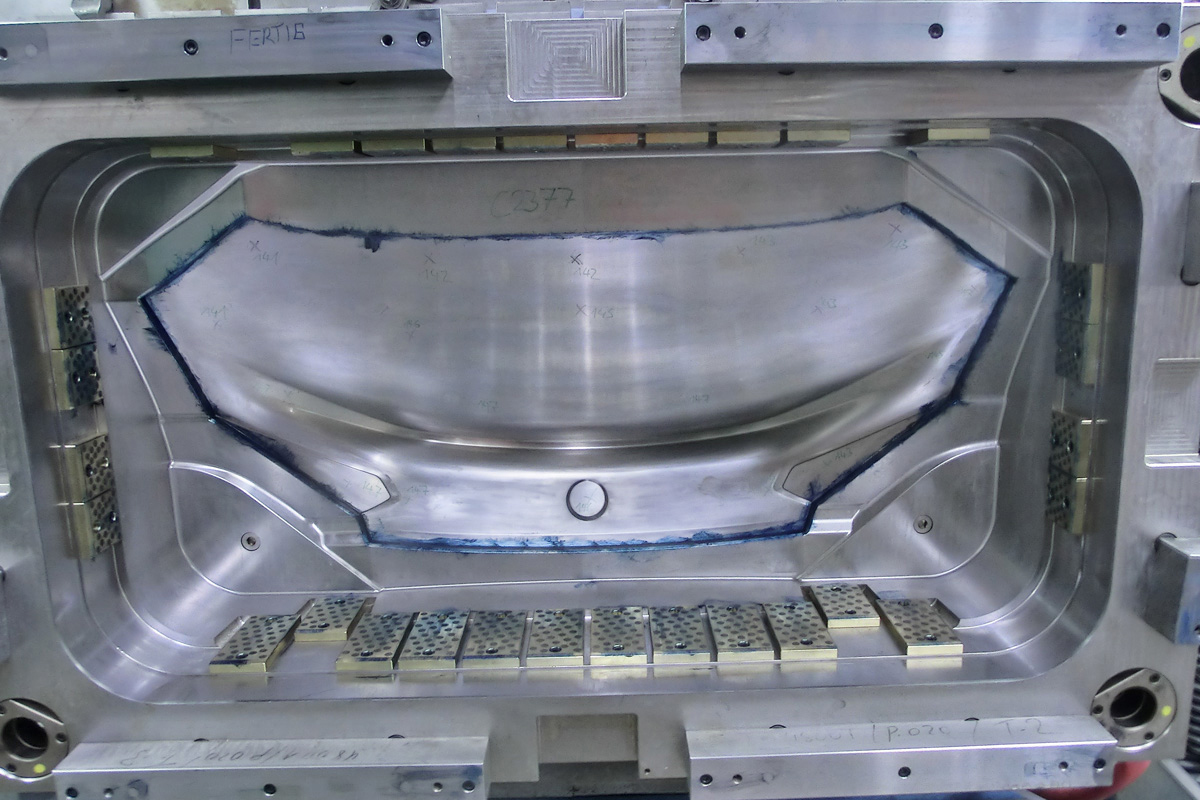

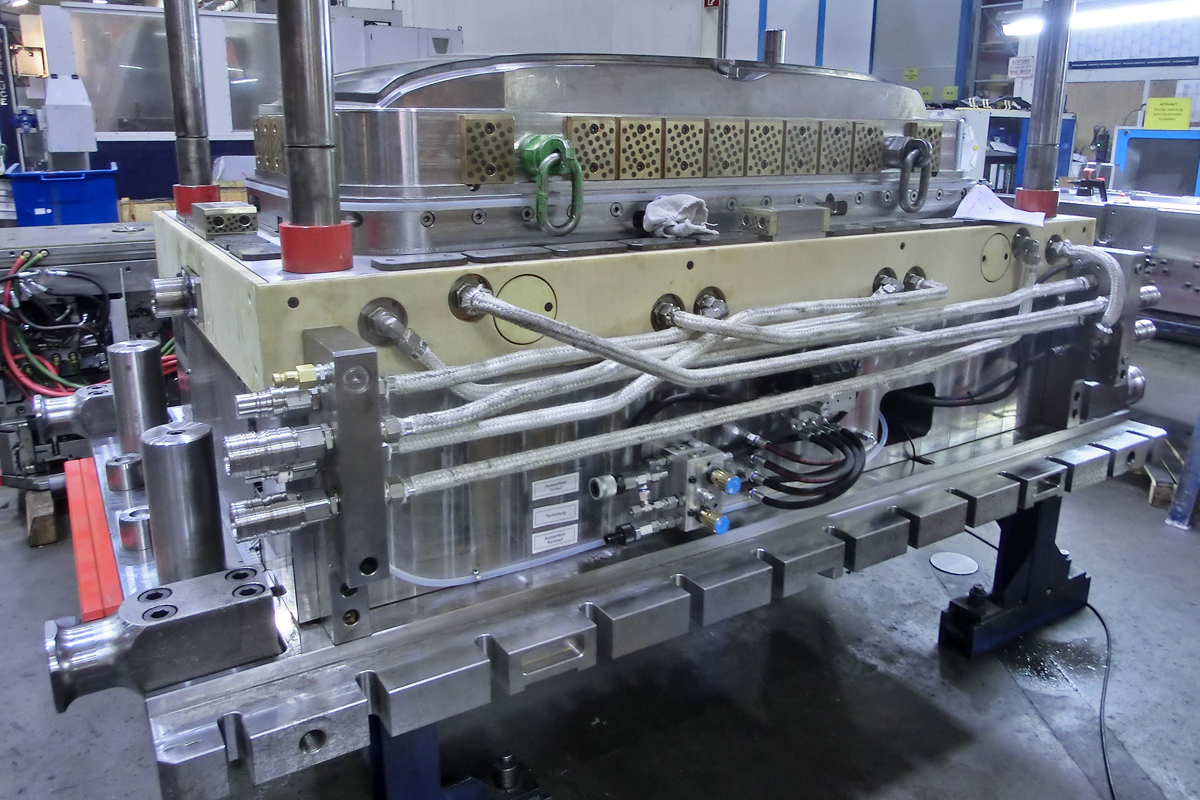

CF RTM tools

- Preform, trimming and cooling tools

- Optional laser hardening for fiber clamping

- Experience with the implementation of different sealing and ejector concepts

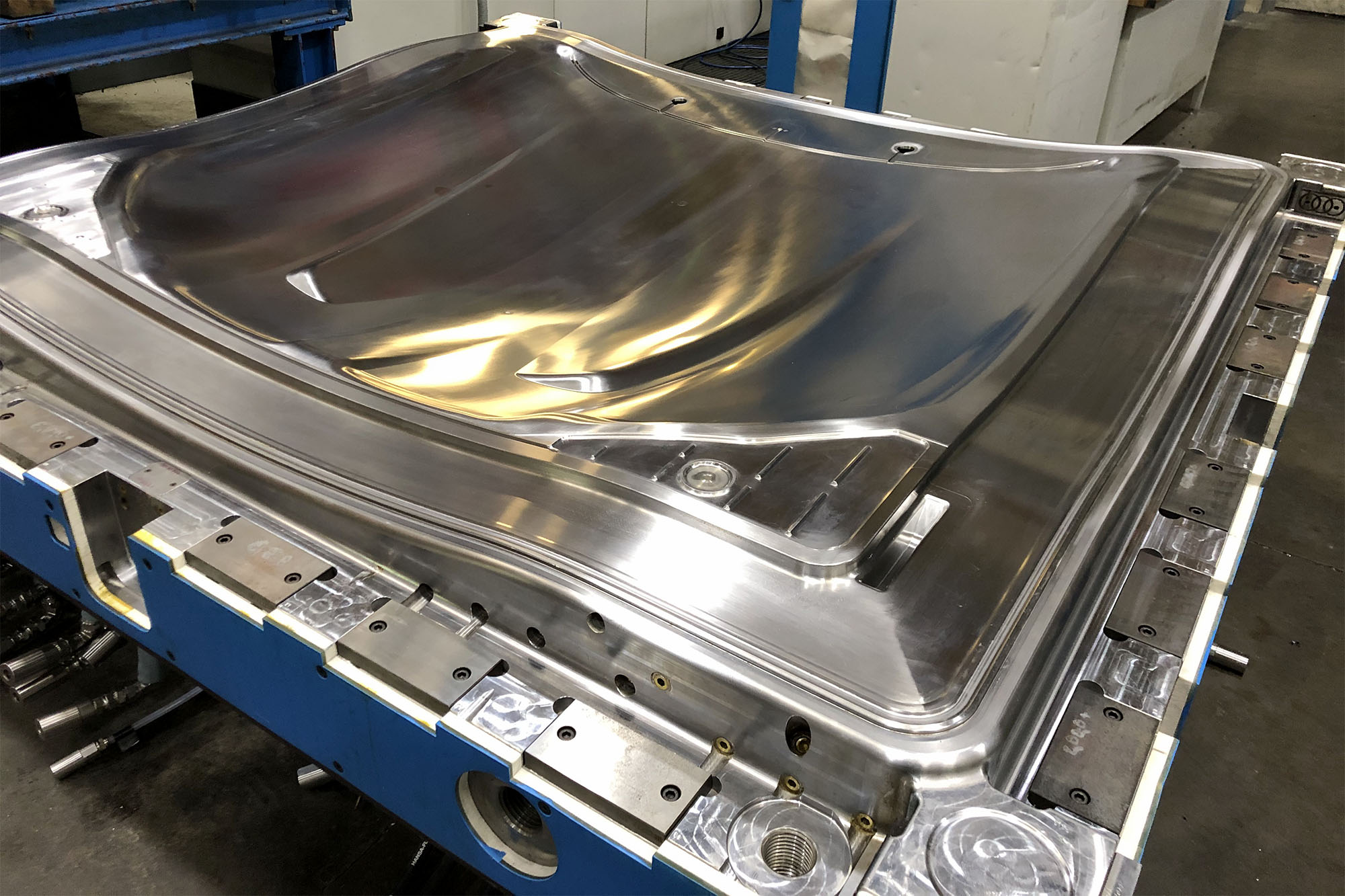

CF wet pressing tools

- Precise fiber tension and orientation through segmented hold-down technology developed by Koller

- Innovative design of the process surface ensures optimum resin leakage and component ventilation

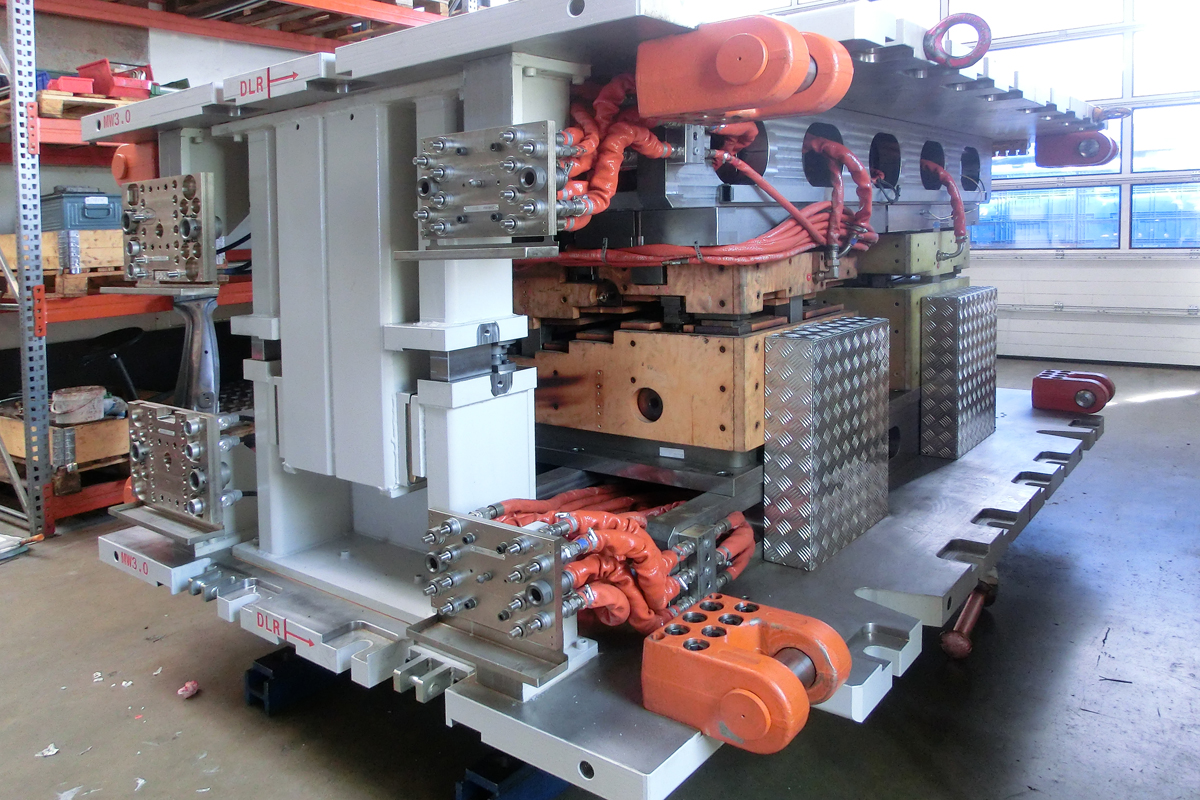

CF Hybrid tools

The part lifter gas spring and foil hold-down concept introduced by Koller enables:

- Koller Seal & Overcooler Concept (sheet metal-metal transition)

- Highest spotting requirements

PU Press tools

- Press tools for sandwich sizes up to 2.5m

- modular design for multiple cavities

- high stability due to special pinch edge technology

- one shot technology

- Weight-optimized tool design

- different heating media can be used

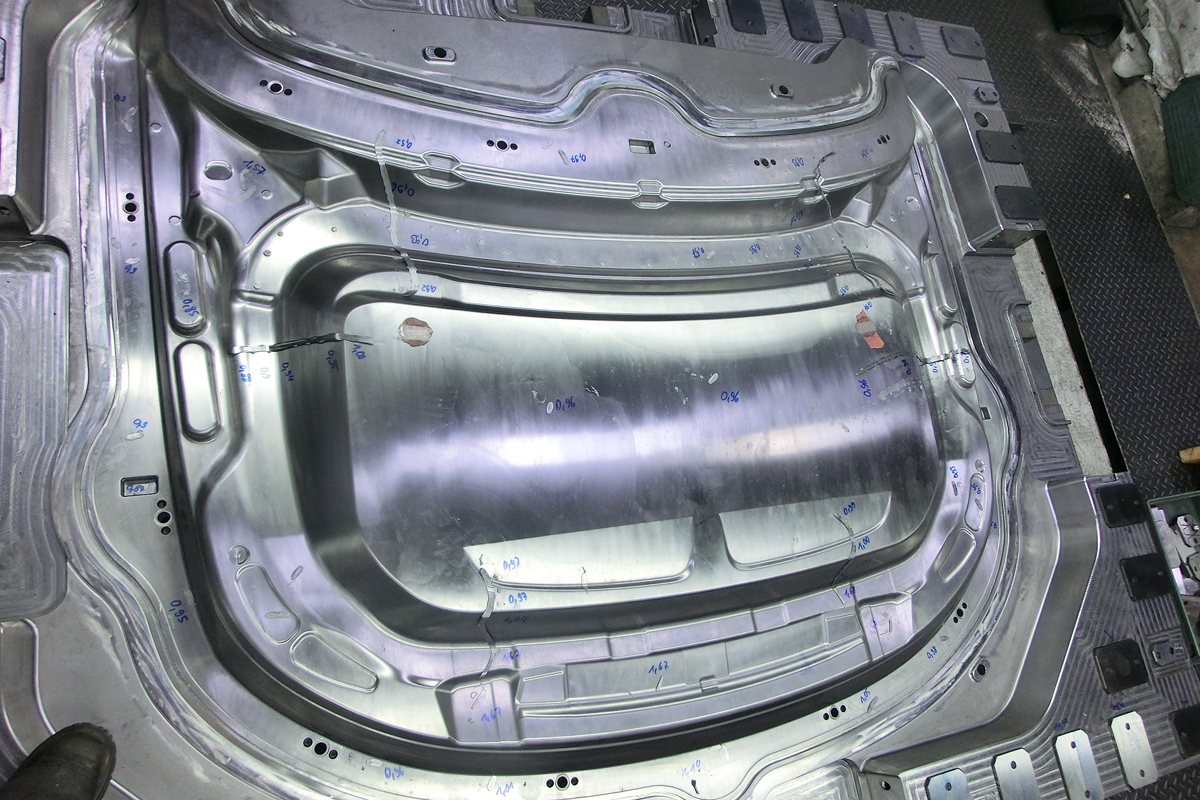

SMC tools

- integrated vacuum technology

- IMC in-mold coating capable

- Class A surface executable

- Hard chromed surfaces possible

- Dive edge version for circumferential trimming