Koller innovative technologies vision

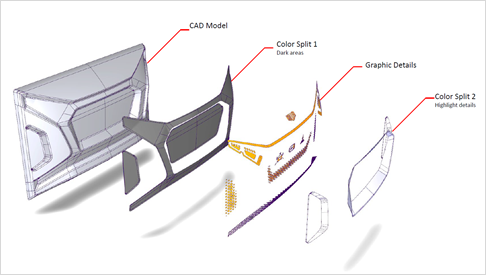

With Koller K.I.T. vision, Koller Group delivers a unique technology that creates new possibilities for large design components as well as exterior components with function integration, such as front modules for EVs.

Part of the development is the cost-saving and resource-saving injection molding process with the associated molds for novel applications.

Technology

- Weight saving:

Realization of large, thin-walled components with wall thicknesses as thin as 3 mm. - Function integration:

Low-pressure injection molding allows sensors to be inserted and overmolded directly - One-shot process:

High process reliability, cost savings by avoiding additional, costly processing steps, such as painting or lasering - Variety of variants:

molded part geometry can be combined with any design elements

Cascadic filling possible, analogous to standard injection molding

K.I.T. vision Benefits

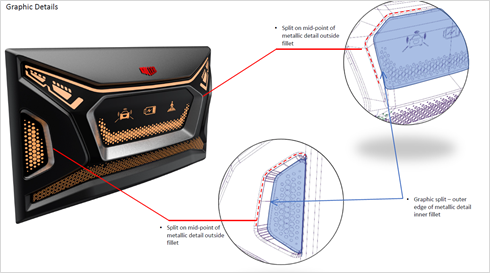

- 3D contours with strong degrees of deformation and small radii allow great design freedom

- Koller K.I.T. vision allows very high positional accuracy of the symbols in combination with disappearing effects

- Due to the direct connection, no subsequent machining steps such as milling, cutting, deburring are required

Realisierung

- Product idea and technology, process know-how of KOLLER Kunststofftechnik combined with the

- tooling know-how of KOLLER Formenbau

- in cooperation with the following partners

Cooperation partners

Consultation and production foil moldings using high-pressure forming

Consultation, foils and injection material

Color printing technology

Hard Coat

Electrically adjustable hot runners

Your contact at Koller

Ralf Utescheny

Head of Innovation Management and Network-Coordination

+49 172 62 11 22 3

r.utescheny@koller-gruppe.de

Florian Marksteiner

Business Development

+49 151 55 10 62 24

f.marksteiner@koller-gruppe.de