The Koller Group is a global technology company headquartered in the heart of Bavaria. We develop and manufacture plastic tools, PUR honeycomb sandwich boards, lightweight systems, ready-to-install components and injection-molded parts in small and large series, primarily for the automotive industry.

Characteristic of KOLLER: From the vision, through component development to industrialization and series production, we present the entire value chain for our CUSTOMERS globally.

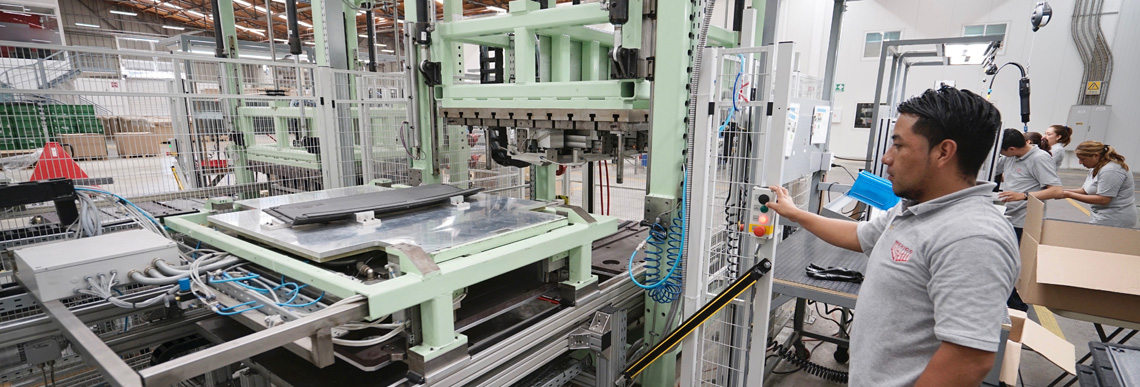

All tools, equipment, test gauges and operating material are manufactured in our own tool shop to your requirements and in combination with our special know-how. The production of the series parts takes place globally at our certified production sites.

Lightweight – innovative – customized

With Koller in good shape

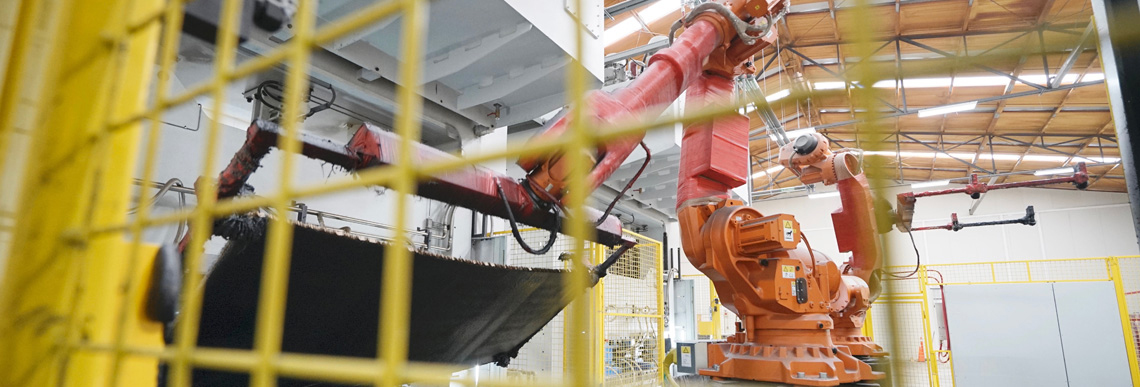

K.I.T. – KOLLER innovative process technologies

CFRTP Technology by Koller

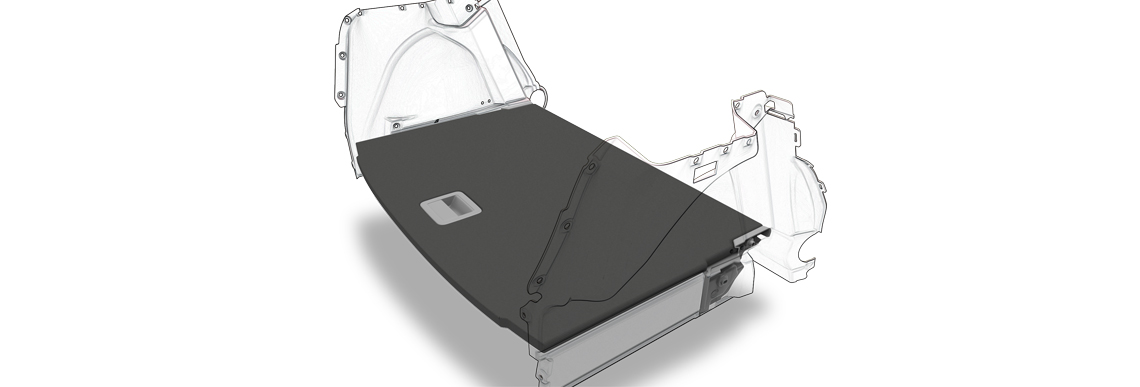

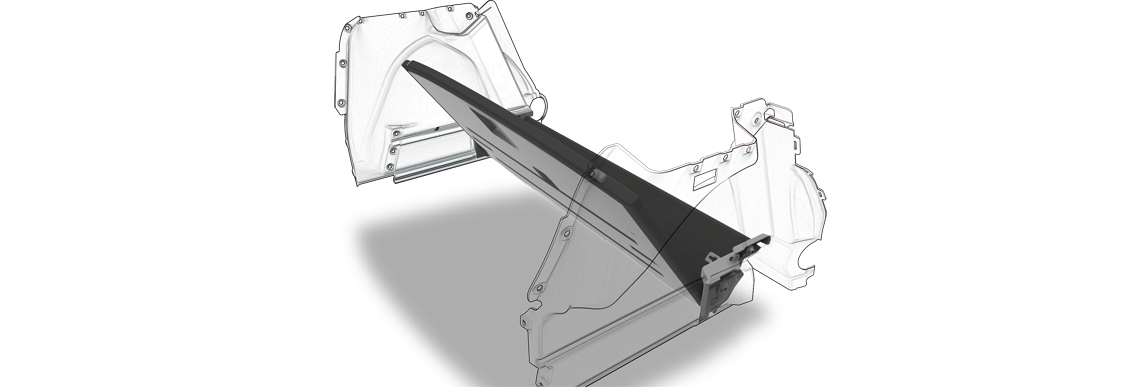

Since the beginning of 2023, KOLLER has been producing and supplying a unique structural component for the chassis of the BMW IX to the BMW plant in Dingolfing. The industrialization of the so called CFRTP-Heckfensterrahmen was implemented in close cooperation with BMW Landshut very successfully within a very short time. All production lines were built completely new, special attention was paid to energy-efficient systems. The Heckfensterrahmen is a so called bionic structural component in hybrid skeleton lightweight design. KOLLER became the world’s first TIER1 series supplier to produce automotive structural components in this technology alongside BMW itself.

The Heckfensterrahmen is built as a thermoplastic composite with steel parts and carbon fibre this makes it very special and unique. The carbon fibre is embedded in a thermoplastic matrix and only used in a load path-oriented manner. The system itself is 100% recyclable and reusable. The use of materials is reduced to a minimum – thanks to load-path oriented geometry. The parts are produced with 100% green electricity in our plant in Lupburg. The technology goes hand in hand with the GREEN KOLLER strategy and contributes a significant step towards C02 neutral production.